Occupational Noise Assessments

Employers and PCBUs have a duty to protect workers from noise-induced hearing loss. To effectively manage and reduce the risks associated with exposure to hazardous noise, and meet compliance requirements, you need to identify unsafe noise, put in place the appropriate controls and monitor them on a regular basis.

What Is The Purpose Of An Occupational Noise Assessment?

An Occupational Noise Assessment (ONA) will help you to ensure the health and safety of your employees exposed to noise. Using the latest noise monitoring equipment, it will determine how loud the noise is and how long employees are exposed to it.

The purpose of an ONA is to:

- Protect Worker Health and Safety: Prevent noise-induced hearing loss (NIHL) and other health issues by identifying and mitigating harmful noise exposure

- Ensure Regulatory Compliance: Ensure your workplace adheres to national exposure standards and OHS/ WHS Legislation

- Improve Workplace Conditions: Identify and control excessive noise to create a safer and more efficient workplace

What Are My Occupational Noise Compliance Requirements?

You have a duty of care to identify and assess any noise risks to your employees and others. Once a noise risk has been identified, you must carry out an Occupational Noise Risk Assessment within the workplace.

The noise testing assessment should be repeated at least every five years or whenever:

- New machinery is installed

- Work processes are altered

- Workspaces are modified

- The length of time workers spend in noisy environments changes

- Employees report hearing issues, difficulty communicating, or discomfort due to noise

Our Occupational Noise flowchart summarises what you need to do and how often.

Learn about Daily Noise Exposure Limits

JTA’s Occupational Noise Assessment Process

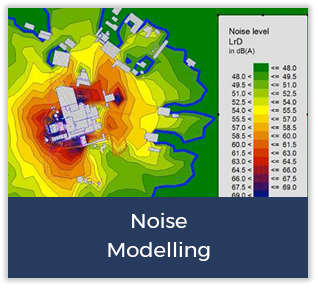

Our ONA measures noise levels generated by machinery and processes, identifies employees exposed to unacceptable noise levels and provides noise control options to reduce inappropriate noise. It systematically evaluates noise levels in your workplace to ensure they are within safe limits set by regulatory bodies.

Over the course of the assessment, our consultant will:

- Identify Noise Sources: Determine which machinery, equipment or processes contribute to high noise levels

- Measure Noise Levels: Use specialised equipment, such as sound level meters or dosimeters, to measure the intensity of noise in decibels (dB)

- Evaluate Exposure: Assess how long workers are exposed to noise levels to evaluate their total exposure over a workday

- Compare to Standards: Compare the measured noise levels and exposure times to occupational safety standards to determine if they exceed permissible limits

- Identify At-Risk Workers: Determine which workers are at risk of hearing damage or other health issues due to noise exposure

- Document Findings: Provide a detailed report documenting noise levels, exposure assessments and recommended control measures, including engineering controls, administrative controls and/or personal protective equipment

You should conduct an ONA when noise is considered to be a problem and:

- Employees have to raise their voices to communicate at a distance of 1 metre, OR

- Employees have a temporary reduction in hearing or ringing in the ears after leaving work for the day

The risk of noise-related injury depends on how loud the noise is and how long the worker is exposed to it. Noise exposure measurements are taken at an employee's ear position.

Regulations set the exposure standard for noise in two parts :

- 85 decibels averaged over an 8-hour period

Machines like blenders, lawnmowers and leaf blowers are around 85 decibels. This rule changes depending on decibels and the time exposed. For example, the risk at 91 decibels over two hours is the same as 85 decibels over eight hours.

- Workers must not be exposed to a noise level above 140 decibels

Any exposure above this level could instantly damage hearing. Sledgehammering or gunshots can be 140 decibels or higher.

OHS/WHS Regulations stipulate that employers have a duty of care to ensure that:

- Employees are not exposed to noise which can harm their health and safety

- Hearing protection and signage are provided if noise exceeds the Noise Exposure Standard

- Audiometric testing of employees is provided if they are required to wear hearing protection

Regulations have a hierarchy of noise controls to protect employees when they operate in hazardous noise areas. It consists of the following:

- Elimination – Physically removing the noise source

- Substitution – Replacing the noise source with a quieter alternative

- Engineering - Modifying the equipment to produce less noise

- Administrative – Changing the way work is done to reduce exposures to noise

- Hearing protection – Donning personal protective equipment

How Is Workplace Noise Measured?

Workplace noise is usually measured using a sound level meter which measures and records the level of decibels in the surrounds. A more precise and effective approach to measuring noise exposure levels is by using personal noise dosimeters. These are noise monitoring devices that are placed on the shoulder of the operator and record noise levels over the course of the shift. As the dosimeter is placed close to the ear, it accurately represents the noise levels that operators are exposed to.

At JTA, we believe that dosimetry is essential for accurately determining worker exposure levels in various scenarios, including engaging in multiple tasks with different noise sources, single tasks with complex noise profiles, tasks with exposures nearing the standard, and tasks that are challenging to assess with only a sound level meter.

To ensure that we provide the most accurate assessments, we incorporate state of the art dosimetry equipment into our regular noise assessments. Our dosimeters can do all of the functions standard dosimeters can but with some valuable extra capabilities such as recording octave band data, high vibration levels and statistical noise levels.

Noise can have temporary and permanent effects. Repeated exposure to loud noise over time may cause permanent hearing loss. This is called Noise- Induced Hearing Loss (NIHL) and it usually happens over many years. How much hearing loss a person has depends on the noise level, how long they are exposed to it, and their susceptibility. NIHL can also happen from sudden loud noises, like explosions, gun shots or heavy hammering. If the noise is loud enough, the damage can be immediate. NIHL can't be repaired.

Audiometric Testing

Most State OHS/WHS regulations require employees who need to wear hearing protection to do their job to undergo Audiometric Testing:

- Within three months following the commencement of employment

- At any time when reasonably requested to do so by the health and safety representative of the designated work group

- At least every two years (results cannot be legally compared to the previous test results if not done within this specified time period)

As a matter of convenience, we provide mobile onsite Audiometric Testing at a time to suit you and your workforce, no matter what shifts they work. Read more about our Audiometric Testing.

FAQs

An occupational noise risk assessment should be conducted by a competent person who is someone:

- With knowledge and understanding of the Noise Regulations

- Who has the ability to use the correct measurement equipment

- Who can record and interpret the results obtained in accordance with the regulations

- Who can make suitable and appropriate recommendations on how the noise levels can be reduced and so reduce the risk of hearing damage occurring

Conducting regular noise testing and implementing effective control measures can lead to cost savings by:

- Reducing the risk of occupational hearing loss

- Improving productivity through reducing the number of employees required to wear hearing protection or needing audiometric testing

- Avoiding legal penalties for non-compliance

Personal protective equipment (PPE) can be used if all other controls do not reduce the noise levels to an acceptable level. The appropriate level of hearing protection to be used must correspond with the level of noise exposure. Common types of hearing PPE are:

- Earmuffs

- Earplugs (disposable or individually moulded)

- Ear canal caps or semi-inserts

When selecting hearing protection, you must ensure that the level of noise entering the worker’s ears is reduced to below the exposure standard for noise. If a worker needs to frequently wear personal hearing protection to protect them from noise above the noise exposure standard, you must provide the worker with regular audiometric testing.

All workers should be provided with Noise Awareness Training to provide them with an understanding of why noise can be harmful and how hearing protection and noise controls can reduce the risks. The training should cover:

- What noise is and how to assess it

- Possible health effects due to noise

- The noise exposures in the particular workplace and the control measures used to protect workers

- Legal responsibilities for controlling excessive noise in the workplace

- Control measures used in the workplace for the protection of exposed workers

- Correct use of personal hearing protectors

If the protection provided by personal ear protection is too high, workers could be overprotected. This makes crucial communication difficult because they can’t hear their coworkers talking. It can also diminish a person’s ability to hear critical noises such as warning signals/sounds and moving vehicles, so it can actually prove detrimental to a person’s immediate safety.

Other Noise Management Services

Occupational Noise

Environmental Noise

Call 1 300 856 282

Speak to our friendly team

Ask a Question

Use our online enquiry form for a quick quote

Newsletter Sign up

Get the latest legislation changes and news updates