Health Risk Assessments

Our Health Risk Assessment is a proactive way to manage occupational health risks across high-hazard industries such as construction, mining, and manufacturing . It is a vital tool in safeguarding the long term health and well-being of your workers whilst ensuring that you are compliant.

What Is The Purpose Of A Health Risk Assessment?

A workplace Health Risk Assessment will show the hidden dangers within your workplace. This health hazard evaluation allows you to identify hazards (such as dust, noise, chemicals, or vibration) that could impact the health of your employees. Unlike a safety risk assessment, which focuses on immediate injury risks, this assessment targets the risk to workers health from long-term exposure. By identifying hazards in the workplace that could cause harm to your workers we can determine whether you have taken enough precautions or should do more to prevent harm. In addition, it is a proactive way to ensure compliance with regulatory standards and fosters a culture of health risk prevention within the workplace.

Specifically, an Occupational Health Risk Assessment looks at:

- The nature of hazards present in the workplace

- The level of exposure that employees face

- The potential risk associated with each exposure

A Health Risk Assessment focuses on exposures that can lead to long-term illnesses (e.g. cancer, hearing loss, respiratory issues), while a safety risk assessment typically focuses on immediate physical injuries (e.g. slips, falls, machinery hazards).

Occupational Exposure Limits (OELs), also known as Workplace Exposure Limits (WELs), are regulatory values that define the maximum safe concentration of a hazardous substance in the workplace. They are based on the potential health effects of exposure to a substance, considering both short-term and long-term risks.

Do I Need A Health Risk Assessment For Compliance In Australia?

Under the Work Health and Safety Act, you have a duty to identify, assess and control hazards that pose a risk to both the health and safety of your employees. This involves:

- Identifying hazards in the workplace

- Assessing risks

- Developing control measures

- Regular monitoring and review

Managing Risks To Health And Safety At The Workplace Fact Sheet

We recommend a formal assessment every 2–3 years or whenever:

- Processes change

- New equipment or chemicals are introduced

- Incidents or health complaints arise

- Your workforce structure changes

JTA’s Occupational Health Risk Assessment Process

The key component of our assessment is a structured walkthrough of your site conducted by one of our experienced Occupational Hygiene consultants. This enables us to observe potential health hazards and the levels of exposure.

Our step by step process:

- Initial Consultation – We'll discuss your site and working environment over the phone. We may request some documentation to ensure we are briefed for the walkthrough.

- Site Walkthrough – We’ll walk through and audit your workplace alongside a site contact

- Identification of Similar Exposure Groups (SEGs) in your workplace

- Pinpoint hazards relevant to each SEG (e.g. noise, dust, chemicals, manual handling)

- Assess the effectiveness of current controls

- Hazard & SEG Mapping – We map SEG group and the identified hazards

- Apply a risk rating to each hazard

- Summary Report – You’ll receive a clear action plan and recommendations for managing your workplace health risks

This type of health hazard evaluation will give you a clear visual of your health risks together with recommendations for risk mitigation providing a strong foundation for budget and control planning.

Common health hazards we look for include:

- Airborne contaminants (dust, fumes, gases)

- Noise and vibration

- Manual handling and repetitive strain

- Hazardous chemicals

- Thermal stress (heat or cold)

- Biological hazards (mould, bacteria)

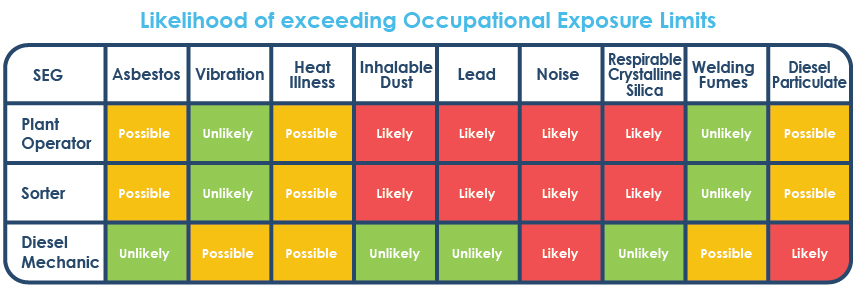

A SEG is a group of workers who perform the same or similar tasks and are likely exposed to the same types of health hazards. For example, welders, fitters, or process line workers may each be SEGs depending on their tasks and work environment. Instead of assessing each individual, SEGs allow for more efficient and focused health monitoring by grouping workers with similar exposures.

Grouping workers into SEGs helps us to efficiently assess and manage exposure risks across the workforce. It avoids duplication and ensures monitoring and controls are targeted where they’re needed most. In addition, using SEGs can lead to significant savings in resources, as fewer samples need to be collected and analysed.

Mitigation controls can only be effective if they are used properly. They also need to be maintained and managed effectively. There are many examples where expensive control measures are installed only for them to remain unused, used infrequently, used incorrectly or poorly maintained and therefore making them ineffective.

JTA’s Risk Mapping

This is an example of the way we will visually present our mapping of your SEGs, hazards and risks so that it is an easy to understand guide for you to quickly identify where you need to take action.

What Are The Benefits?

- Comprehensive hazard identification - go beyond what's obvious and uncover unseen risks

- Data-driven decision making - direct resources toward your highest-risk areas

- Audit-ready documentation - be prepared for external scrutiny and internal reviews

- Improved health outcomes- protect your workforce with targeted controls

FAQs

All assessments are carried out by experienced JTA consultants with qualifications in occupational hygiene, workplace health, and WHS legislation.

Not at all. We conduct walkthroughs while operations are running as it allows us to observe real tasks and identify genuine exposure scenarios.

- Elimination - Removing the hazard altogether

- Substitution - Replacing a hazardous substance or process with a safer alternative

- Engineering control - Implementing physical changes to reduce exposure to hazards

- Administrative controls - Implementing procedures and policies to manage risks

- Personal protective equipment (PPE) - Providing and ensuring the use of appropriate PPE

Absolutely. A Health Risk Assessment is often the first step to developing an occupational hygiene monitoring plan. It identifies which SEGs require personal exposure monitoring for dust, noise, gases, or other hazards.

- Management: Responsible for providing resources and ensuring the process is followed

- Supervisors: Familiar with workplace activities and can identify hazards

- Employees: Their knowledge and experience can be valuable in identifying hazards and implementing controls

Other Occupational Health & Safety services

Call 1 300 856 282

Speak to our friendly team

Ask a Question

Use our online enquiry form for a quick quote

Newsletter Sign up

Get the latest legislation changes and news updates