Crystalline Silica Dust Monitoring

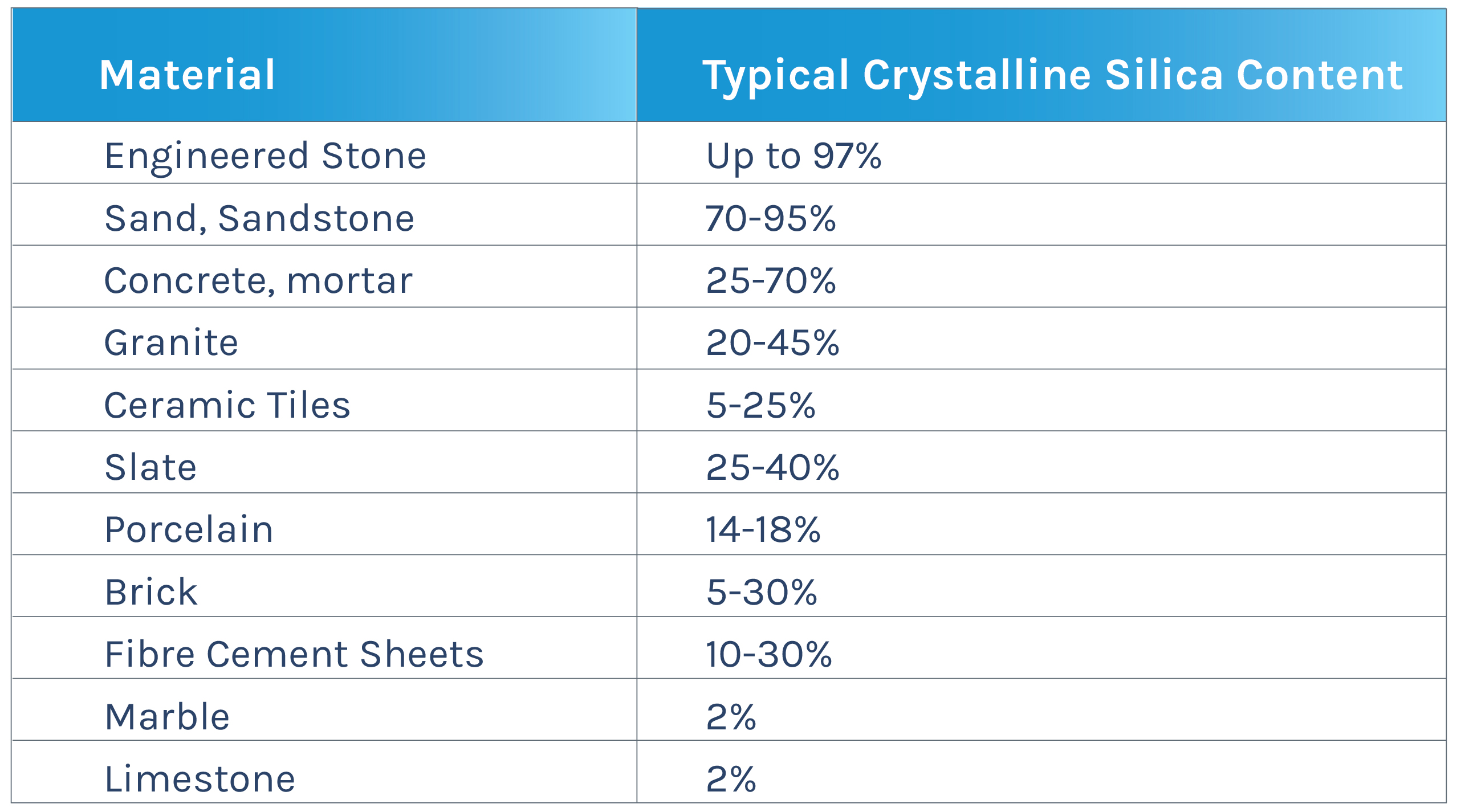

Crystalline Silica is found in natural and man-made materials such as engineered stone, granite and sandstone as well as building materials such as concrete, bricks, tiles and mortar. Excessive exposure to fine dust created when these materials are cut, ground, drilled or polished can lead to potentially deadly health conditions such as silicosis or lung cancer.

Your Duty In Relation To Crystalline Silica

Under OHS/ WHS Regulations, you have specific duties to manage the risks to health and safety when employees are using, handling, generating and storing hazardous chemicals, including silica. You must ensure that your employees are not exposed to Respirable Crystalline Silica dust at a level above the exposure standards for airborne contaminants set by Work Safe Australia.

Air monitoring must be conducted if there is any uncertainty that the exposure standard is being exceeded or to find out if there is a risk to a worker's health. Ongoing health monitoring may then be required.

How JTA Can Help

Crystalline Silica is a risk to health when respirable dust is generated, becomes airborne and is inhaled. The assessment of health risk is a critical part of determining the need for and level of control required to make the products and processes safe and prevent exposures capable of triggering silicosis. JTA’s experienced and skilled Occupational Hygienists can conduct air monitoring using specialised equipment which separates the fine particles of interest from other dusts. The samples are then analysed to identify the concentration of Crystalline Silica in the collected dust enabling us to measure the concentration of respirable silica in a workers’ breathing zone, identify high risk exposures and advise on suitable, effective, practicable controls.

Crystalline Silica Monitoring Includes:

- Preliminary consultation to determine cost effective testing method

- Site visit by an experienced JTA Occupational Hygienist

- Air monitoring (as per AS 2985-2009) to determine actual exposures to respirable dust

- Specialised analysis and determination of respirable Crystalline Silica exposure

- Assessment in close consultation with site personnel to identify how best to meet compliance obligations.

- Written report meeting AIOH reporting recommendations detailing observations, sampling and analytical results, compliance obligations and recommended control measures

Types Of Crystalline Silica

Silica is silicon dioxide, a naturally occurring widely abundant mineral that forms the major component of most rocks and soils. There are non-crystalline and crystalline forms of silica.

Non-crystalline silica does not cause lung damage whilst small crystalline silica dust particles are hazardous as they can penetrate into the lungs and lead to lung damage and disease.

Crystalline silica is normally safe to handle and not a risk to the health of your workers when it is in a solid form and left undisturbed. However, it becomes a hazard when the material containing it is disturbed by grinding, sawing or drilling. These activities then create very fine silica dust which becomes airborne and is easily inhaled by workers and is known as Respirable Crystalline Silica.

Exposure to Respirable Crystalline Silica can lead to serious respiratory diseases such as silicosis, progressive massive fibrosis, chronic obstructive pulmonary disease, chronic bronchitis, and lung cancer. Respirable Crystalline Silica also increases the risk of developing chronic kidney disease, autoimmune disorders, and other adverse health effects.

The Engineered Stone Prohibition means that you must not process, or direct or allow a worker to process engineered stone unless the processing of the stone or product is controlled. For processing to be controlled you must put in place control measures to eliminate or minimise risks so far as is reasonably practicable. Control measures can include wet cutting, on-tool dust removal, local exhaust ventilation, and breathing protection. In certain situations you can apply to a WHS regulator for an exemption for a type of engineered stone. Work Safe Australia has compiled an Exemption Flowchart.

What Is The Engineered Stone Prohibition?

The Engineered Stone Prohibition came into effect in Australia on 1st July 2024. This means that a person conducting a business or undertaking (PCBU) must not carry out, or direct or allow a worker to carry out, work that involves the manufacture, supply, processing, or installation of engineered stone benchtops, panels, and slabs. The decision to implement this ban was in response to the unacceptable number of engineered stone workers who have developed Silicosis in Australia. As a person conducting a business, it is important to understand what this ban means for you and how you conduct your business.

2024 - Key Regulation Changes

The ban applies to all materials containing at least 1% crystalline silica, including engineered stone.

In relation to engineered stone, the key changes are:

- Permitted processing of engineered stone to be controlled and notified to the regulator

- PCBUs to undertake a risk assessment of any permitted processing of legacy engineered stone

- Additional duties for PCBUs carrying out permitted work with engineered stone that is assessed as high risk.

You can continue to work with legacy engineered stone for limited purposes. Legacy engineered stone includes any benchtop, panel, or slab that is already installed and, for the purposes of disposal, includes engineered stone benchtops, panels and slabs whether installed or not installed (such as a stockpile).

View Safe Work Australia’s Notification Flowchart to understand when you have to notify a WHS regulator if you want to process legacy engineered stone.

Definition of Engineered Stone

Engineered stone is defined as an artificial product that:

- Contains at least 1% crystalline silica as a weight/weight concentration

- Is created by combining natural stone materials with other chemical constituents (such as water, resins, or pigments), and becomes hardened

Engineered stone does not include:

- Concrete and cement products

- Bricks, pavers, and other similar blocks

- Ceramic wall and floor tiles

- Sintered stone

- Porcelain products

- Roof tiles

- Grout, mortar and render

- Plasterboard

Call 1 300 856 282

Speak to our friendly team

Get a Quote

Use our online enquiry form for a quick quote

Newsletter Sign up

Get the latest legislation changes and news updates

Our Related Services

- Indoor Air Quality assessments test the work environment for air contamination

- OHS Management Systems provide a systematic approach to managing health and safety risks

- Hazardous Materials Audits identify and control hazardous material risks

- Asbestos Air Monitoring and Clearance Inspections monitors air during asbestos removal and provides a clearance certificate

- Hazardous Substances & Dangerous Goods ensures safe management of potentially dangerous chemical substances and hazardous materials

- Secondment & Outsourcing for practical in-house OHS advice and support when you need it